Just thought this would be a cool new topic. If there is already one in existence please let me know so I can delete this one, or a mod can do it. As for me I finished my under tail project and rode the crap out of it.

What did you do to your SV today? (mods, farkles, maintenance, etc)

1 reading

On1wheel01

15,181 - 15,200 of 15,883 Posts

Joined

·

11,502 Posts

someone say leverage?If you aren't using a rack that's cantilevered like the Givi unit, then your assessment is pretty well spot on.

Leverage is a b!tch.

Joined

·

2,656 Posts

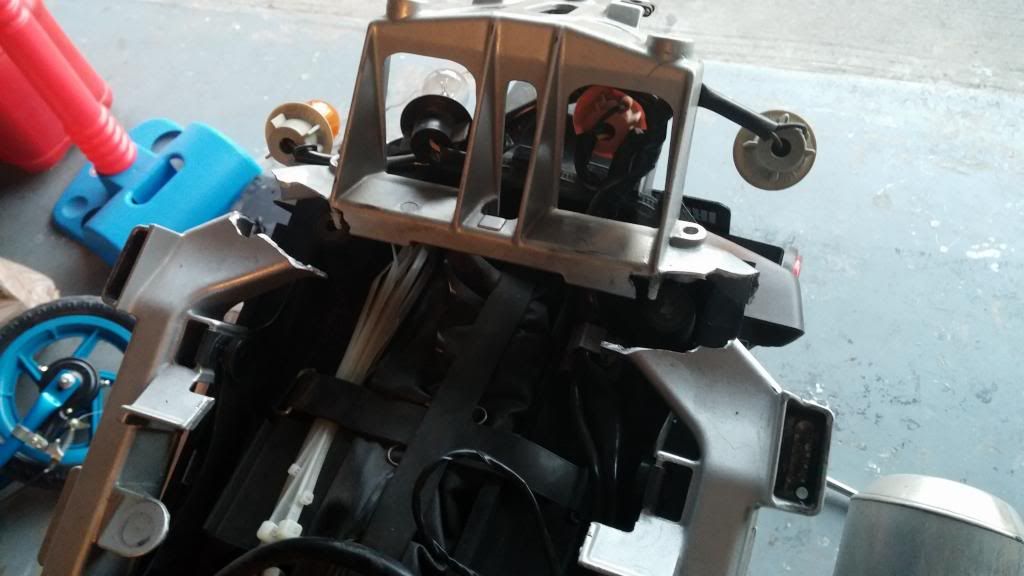

Like this? Extending up and under the subframe?If you aren't using a rack that's cantilevered like the Givi unit, then your assessment is pretty well spot on.

Leverage is a b!tch.

My thoughts on why it failed: That rack vibrates (it's not exactly light weight.) It's been there for over 30k miles (probably closer to 40k), and has been used on a freeway that undulates sharply on a daily basis for 2 years solid - about 15 miles of harsh pavement each way. I think that this, over time, work-hardened the aluminum until it finally failed.

Is the rack like cantilevered off the back? If so, would this not put a twisting moment into the subframe brace that was designed for a straight down pillion load. More and different bracing sounds like it would be beneficial here. Maybe start a thread with pics and the collective brain-trust of SVR might come to the rescue!

Joined

·

7,186 Posts

Re: Cantilevered? Yes. But I'm thinking of just not running with the rack for now... Other thoughts I've had would be to run bracing forward to the front rear seat brace, but that would require welding, and time, neither of which I have access to...Is the rack like cantilevered off the back? If so, would this not put a twisting moment into the subframe brace that was designed for a straight down pillion load. More and different bracing sounds like it would be beneficial here. Maybe start a thread with pics and the collective brain-trust of SVR might come to the rescue!

Today...I did something to the bike that I haven't done for over 4 years....I got it Inspected! Feels really weird to not be doing something illegal (for once). The mechanic looked at the old sticker and said 'you haven't got inspected for over 4 years!'...like this was something horrible. Maybe it is...but that's one thing I really don't worry about because I take good care of the machine and don't need someone else telling me if it needs work.

Feels really weird to not be doing something illegal (for once). The mechanic looked at the old sticker and said 'you haven't got inspected for over 4 years!'...like this was something horrible. Maybe it is...but that's one thing I really don't worry about because I take good care of the machine and don't need someone else telling me if it needs work.

And...this fellow (nice guy but didn't seem too know much about sport bikes) says my front tire is right at the minimum...which it's not. The Shinko 011 has two sets of grooves...one deeper than the other and it's the deeper ones that have the wear bar indicators. They're over 3/32 but the shallow ones are just a little under 2/32 and was where he chose to measure..which is incorrect.

Then he says my front brakes are right at the minimum too! Darn..I could swear those pads are fresh..and they are. EBC Extreme Pro's aren't super thick when new and they have a handy little groove in the middle that shows when they're toast...which we're well away from. Actually you can't see the backing plates as they're up inside the caliper still being the pads are so thick. He wrote the sticker so I smiled and said thankyou and left. But this is why I HATE getting Inspections because it's like someone is critiquing my work...which I really don't mind if the person knows what they're doing, but trying to argue with someone when they haven't got a clue is just frustrating.

Funny thing in PA is the Law used to have a small fine for no inspection sticker and a bigger fine for an expired one. So...when it expires you just scrape it off! But they finally wised up a while back and like doubled the 'no sticker' fine over the expired one so I left the old one on until today. Always figured if a Cop is looking at my sticker that infraction is going to be tiny compared to what I did to make him stop me. Being a Legal Eagle is supposed to make you feel good, but I just feel dirty.

And...this fellow (nice guy but didn't seem too know much about sport bikes) says my front tire is right at the minimum...which it's not. The Shinko 011 has two sets of grooves...one deeper than the other and it's the deeper ones that have the wear bar indicators. They're over 3/32 but the shallow ones are just a little under 2/32 and was where he chose to measure..which is incorrect.

Then he says my front brakes are right at the minimum too! Darn..I could swear those pads are fresh..and they are. EBC Extreme Pro's aren't super thick when new and they have a handy little groove in the middle that shows when they're toast...which we're well away from. Actually you can't see the backing plates as they're up inside the caliper still being the pads are so thick. He wrote the sticker so I smiled and said thankyou and left. But this is why I HATE getting Inspections because it's like someone is critiquing my work...which I really don't mind if the person knows what they're doing, but trying to argue with someone when they haven't got a clue is just frustrating.

Funny thing in PA is the Law used to have a small fine for no inspection sticker and a bigger fine for an expired one. So...when it expires you just scrape it off! But they finally wised up a while back and like doubled the 'no sticker' fine over the expired one so I left the old one on until today. Always figured if a Cop is looking at my sticker that infraction is going to be tiny compared to what I did to make him stop me. Being a Legal Eagle is supposed to make you feel good, but I just feel dirty.

Joined

·

1,411 Posts

Btw, yes, this is cantilevered. It supports a load on one end by pushing down on the fulcrum (grab handle) and lifting on the other end (passenger peg).Like this? Extending up and under the subframe?

![Image]()

Its a common problem on Feejers that dont have re-enforcements to help with the load from luggage. Yours is the first I've heard of on the SV.

Joined

·

1,411 Posts

Put some more miles on it and finished off the first tank since getting it running again. I'll put another tank through then check all the torques and give it a post assembly oil change. (after I get back from my trip that is)

Also, the auto-tune is showing some results already and I think I'm getting the hang of what to watch out for in the trim table.

Question; has anyone that uses a radiator guard noticed a slight increase in operation temps after installing it? I made a waste basket special during the bikes down time.

Also, the auto-tune is showing some results already and I think I'm getting the hang of what to watch out for in the trim table.

Question; has anyone that uses a radiator guard noticed a slight increase in operation temps after installing it? I made a waste basket special during the bikes down time.

Joined

·

1 Posts

Cleaned the chain the bike greased up the chain getting ready for the dragon next week.

Joined

·

18 Posts

Put 140 miles on her today through the Colorado mountains/canyons.

Joined

·

18 Posts

Also ordered new front & rear sprockets along with new bar ends.

Joined

·

7,186 Posts

While picking up movie tix for later, parked next to this ugly thing.

Attachments

-

70.8 KB Views: 134

Joined

·

6,196 Posts

^^^^^

Blue isn't THAT ugly......

:hiding2:

Blue isn't THAT ugly......

:hiding2:

Speaking of fuel systems....mine is dropping pressure again at WFO. The pump and filter were freshened back about 22K miles ago and it looks like it's getting restrictive again. I'd left the pressure gauge installed just to keep an eye on it, and especially after seeing how incredibly tiny the filter element actually is...mine is getting an automotive FI filter and bypassing the stupid thing.

The pump and filter were freshened back about 22K miles ago and it looks like it's getting restrictive again. I'd left the pressure gauge installed just to keep an eye on it, and especially after seeing how incredibly tiny the filter element actually is...mine is getting an automotive FI filter and bypassing the stupid thing.

Granted a motorcycle engine isn't going to need nearly the fuel volume compared to a car or truck, but when it needs the fuel it NEEDS the fuel! Mine can consume about 10 gal/hr and the stock filter is dropping pressure badly trying to supply it. Happily I've got AN braided lines and will be able to patch in a Delco GM truck filter pretty neatly ( I hope) which will solve the problem once and for all.

Every other machine on this planet has fuel filter changes as part of their PM...but not Suzuki!! Our filter costs about $250!! I do not kid! This is rediculous and once I've got it adapted the GM filters will cost about $9.00...which is more like it. Put a fresh one on every couple of riding seasons and it'll never have another problem with fuel starvation. This whole thing makes me wonder how many bikes are out there running with fuel pressure dropping? GSXR's share a similar system and now I'm going to be on the band-wagon to get everyone to bypass their filters and put on an external one.

Granted a motorcycle engine isn't going to need nearly the fuel volume compared to a car or truck, but when it needs the fuel it NEEDS the fuel! Mine can consume about 10 gal/hr and the stock filter is dropping pressure badly trying to supply it. Happily I've got AN braided lines and will be able to patch in a Delco GM truck filter pretty neatly ( I hope) which will solve the problem once and for all.

Every other machine on this planet has fuel filter changes as part of their PM...but not Suzuki!! Our filter costs about $250!! I do not kid! This is rediculous and once I've got it adapted the GM filters will cost about $9.00...which is more like it. Put a fresh one on every couple of riding seasons and it'll never have another problem with fuel starvation. This whole thing makes me wonder how many bikes are out there running with fuel pressure dropping? GSXR's share a similar system and now I'm going to be on the band-wagon to get everyone to bypass their filters and put on an external one.

15,181 - 15,200 of 15,883 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.5M

- members

- 80K

- Since

- 2002

A forum community dedicated to Suzuki SV650 owners and enthusiasts. Come join the discussion about performance, modifications, racing, troubleshooting, maintenance, and more!

Top Contributors this Month

View All

Slowhands

225 Replies

Troy Jollimore

97 Replies

Straticus

86 Replies